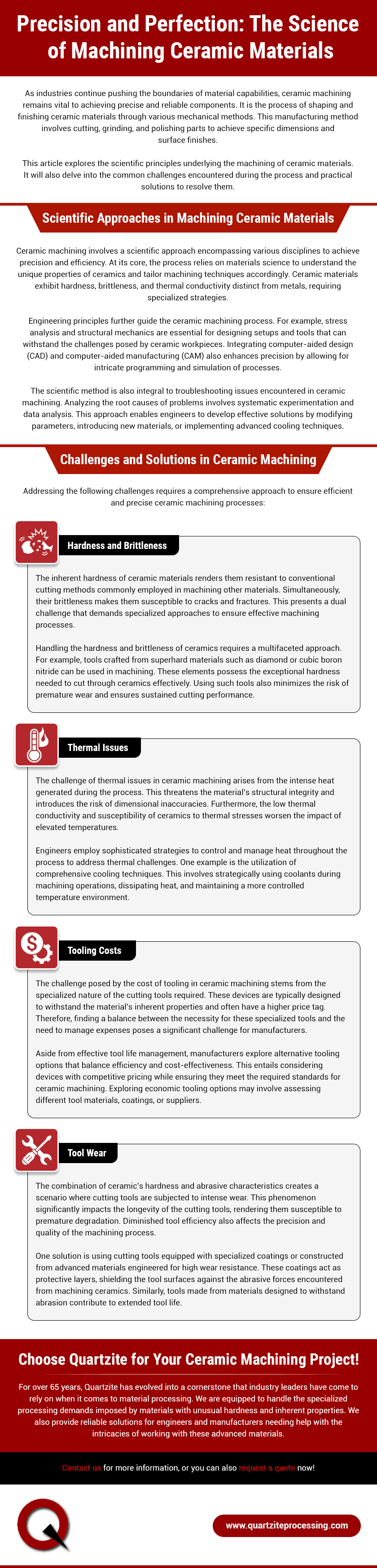

As industries continue pushing the boundaries of material capabilities, ceramic machining remains vital to achieving precise and reliable components. It is the process of shaping and finishing ceramic materials through various mechanical methods. This manufacturing method involves cutting, grinding, and polishing parts to achieve specific dimensions and surface finishes.

This article explores the scientific principles underlying the machining of ceramic materials. It will also delve into the common challenges encountered during the process and practical solutions to resolve them.

Scientific Approaches in Machining Ceramic Materials

Ceramic machining involves a scientific approach encompassing various disciplines to achieve precision and efficiency. At its core, the process relies on materials science to understand the unique properties of ceramics and tailor machining techniques accordingly. Ceramic materials exhibit hardness, brittleness, and thermal conductivity distinct from metals, requiring specialized strategies.

Engineering principles further guide the ceramic machining process. For example, stress analysis and structural mechanics are essential for designing setups and tools that can withstand the challenges posed by ceramic workpieces. Integrating computer-aided design (CAD) and computer-aided manufacturing (CAM) also enhances precision by allowing for intricate programming and simulation of processes.

The scientific method is also integral to troubleshooting issues encountered in ceramic machining. Analyzing the root causes of problems involves systematic experimentation and data analysis. This approach enables engineers to develop effective solutions by modifying parameters, introducing new materials, or implementing advanced cooling techniques.

Challenges and Solutions in Ceramic Machining

Addressing the following challenges requires a comprehensive approach to ensure efficient and precise ceramic machining processes:

Hardness and Brittleness

The inherent hardness of ceramic materials renders them resistant to conventional cutting methods commonly employed in machining other materials. Simultaneously, their brittleness makes them susceptible to cracks and fractures. This presents a dual challenge that demands specialized approaches to ensure effective machining processes.

Handling the hardness and brittleness of ceramics requires a multifaceted approach. For example, tools crafted from superhard materials such as diamond or cubic boron nitride can be used in machining. These elements possess the exceptional hardness needed to cut through ceramics effectively. Using such tools also minimizes the risk of premature wear and ensures sustained cutting performance.

Thermal Issues

The challenge of thermal issues in ceramic machining arises from the intense heat generated during the process. This threatens the material’s structural integrity and introduces the risk of dimensional inaccuracies. Furthermore, the low thermal conductivity and susceptibility of ceramics to thermal stresses worsen the impact of elevated temperatures.

Engineers employ sophisticated strategies to control and manage heat throughout the process to address thermal challenges. One example is the utilization of comprehensive cooling techniques. This involves strategically using coolants during machining operations, dissipating heat, and maintaining a more controlled temperature environment.

Tooling Costs

The challenge posed by the cost of tooling in ceramic machining stems from the specialized nature of the cutting tools required. These devices are typically designed to withstand the material’s inherent properties and often have a higher price tag. Therefore, finding a balance between the necessity for these specialized tools and the need to manage expenses poses a significant challenge for manufacturers.

Aside from effective tool life management, manufacturers explore alternative tooling options that balance efficiency and cost-effectiveness. This entails considering devices with competitive pricing while ensuring they meet the required standards for ceramic machining. Exploring economic tooling options may involve assessing different tool materials, coatings, or suppliers.

Tool Wear

The combination of ceramic’s hardness and abrasive characteristics creates a scenario where cutting tools are subjected to intense wear. This phenomenon significantly impacts the longevity of the cutting tools, rendering them susceptible to premature degradation. Diminished tool efficiency also affects the precision and quality of the machining process.

One solution is using cutting tools equipped with specialized coatings or constructed from advanced materials engineered for high wear resistance. These coatings act as protective layers, shielding the tool surfaces against the abrasive forces encountered from machining ceramics. Similarly, tools made from materials designed to withstand abrasion contribute to extended tool life.

Choose Quartzite for Your Ceramic Machining Project!

For over 65 years, Quartzite has evolved into a cornerstone that industry leaders have come to rely on when it comes to material processing. We are equipped to handle the specialized processing demands imposed by materials with unusual hardness and inherent properties. We also provide reliable solutions for engineers and manufacturers needing help with the intricacies of working with these advanced materials.

Contact us for more information, or you can also request a quote now!